High pressure wash and rinse

sprays, insures

removal of particles, manufacturing soils, chemical contamination

and pyrogens. The result is total cleaning of all wetted surfaces

including

recessed

blind holes in LYO stoppers which retain

water, particulates and silicone (from

pre-siliconization by stopper

manufacturer) due to capillary action.

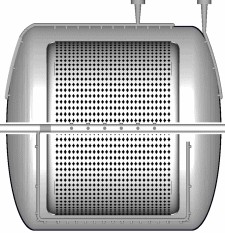

The CIP system is designed into the HUBER

System

processor, an

integral and critical component of the entire process. The

patented CIP nozzle placement ensures consistent washing

and rinsing of entire interior surfaces of the outer drum and the

outer surfaces of the inner drum as they are fully washed and

rinsed as part of every CIP cycle. Thus, you are assured of complete

removal of residual particles with every batch of stoppers processed.

On request, the Sterilizer Series can be designed in such

a way that a subaqual pre-sterilization of the stoppers in a

water bath under pressure up to a temperature of 125

degrees Celsius can be carried through.

Subaqual treatment

allows for the extraction of water

soluble components and mold release agents which

can be hard to remove using conventional hot water

and detergents. As regulatory agencies increase their

expectations for even lower levels of extractable

substances in your rubber stoppers and thus on drug

stability, let us help you attain the lowest extractable

levels achievable.

Air

required for the drying procedure and is brought

into the machine by the blower through a pre-filter and

sterile filter. Drying is enhanced by centrifuging, removing

most of the water from the stoppers prior to the drying cycle.

Intermittent shifting of the stopper load during drying provides

very low moisture levels.

Steam is supplied through nozzles in the center shaft (patented).

By the steam sterilization coming from the center,

a fast removal

of oxygen rich atmosphere from the pressure vessel

is achieved. On request, a pre-vacuum for sterilization is available.

The steam continuously and uniformly is supplied via the nozzles

which

guarantees an optimum temperature distribution. The machine

quickly reaches the required sterilization temperature of

121 degrees Celsius. During sterilization, the stoppers are

smoothly shifted intermittently. Pressure and temperatures

are permanently recorded according to FDA.

On request, a SIP step can be

integrated which exposes

the

inner wall of the stopper vessel and the outer wall of the

inner drum to saturated steam. This insures precise

vaporization of the inner wall of the vessel and outer surfaces

of the inner drum by rotating steam nozzles. This step can also

be used to reliably and completely remove residual silicone oil

from the

vessel interior and the inner drum outer surfaces.

A detailed technical animation of the HUBER

System process

is available upon request.

Please contact us regarding HBPROCESS.gif

Ask us about our

Multi-Media Presentations and Catalogs on CD-ROM !

Ask us about our

Multi-Media Presentations and Catalogs on CD-ROM !