The ideal combination of a washer, sterilizer and drier for washing of rubber

stoppers and rubber articles of the pharmaceutical

and technical

elastomer industry. Treatment of plastic caps,

screw caps,

and aluminum caps.

The DS S Series are double door, pass through designs which are

similar to the DS D series machines, but sterilize the stoppers. The

stoppers are deposited into the sterile suite ready for use or storage

in sterile storage

systems. The DS S Series range from 50 to

375 liters per batch. See also Size Your Machine.

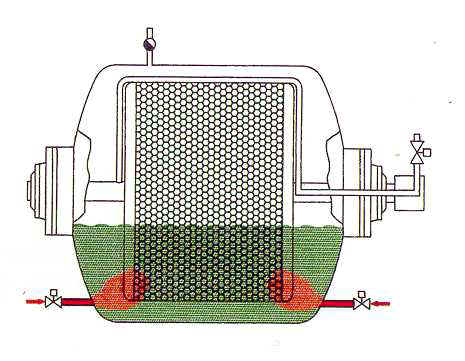

Steam is supplied through nozzles in the center shaft

(patented).

By the steam sterilization coming from the center, a fast removal

of oxygen rich atmosphere from the pressure vessel is achieved.

On request, a pre-vacuum for sterilization is possible. The steam

continuously and uniformly is supplied via the nozzles which

guarantees an optimum temperature distribution. The machine

quickly reaches the required sterilization temperature of

121 degrees Celsius. During sterilization, the stoppers are

smoothly shifted intermittently. Pressure and temperatures

are permanently recorded according to FDA.

The DS S has the following control system:

Allen Bradley LOGIX - which consists of a PLC, PC with

color screen, keyboard and color printer.

The ideal combination of a washer, sterilizer

and drier to treat the

exterior and interior surfaces of pharmaceutical and technical

elastomer rubber and plastic articles with greatest flexibility.

(Click for larger view)

(Click for larger view)

Most

effective cleaning of highly contaminated articles

Most

effective cleaning of highly contaminated articles

as well as articles with deep holes.

Loading from non-sterile side. Ergonomic aseptic unloading at

Loading from non-sterile side. Ergonomic aseptic unloading at

sterile side, even into containers for direct transport to

stoppering

machine. See Sterile

Isolation System SIS and Total Sterile

Transfer TST

There are no

mechanically moving parts during the process,

There are no

mechanically moving parts during the process,

and no metal abrasion, only highly cleaning turbulence of

DIRECT IMPACT CLEANING, CIP and/or SIP, washing each

stopper individually.

Precise

siliconization by using silicone oil or silicone emulsion.

Precise

siliconization by using silicone oil or silicone emulsion.

Optimal

temperatures during each process step, max. uniformity

Optimal

temperatures during each process step, max. uniformity

of temperatures during sterilization by patented system of steam

inlet

and distribution.

Effective

drying under 0.2 micron sterile filtered air or HEPA

Effective

drying under 0.2 micron sterile filtered air or HEPA

filtered air (optional vacuum) with immediate removal of

water drops from deep holes through occasionally intermittent

shifting of stopper (Patent) providing uniform low residual

moisture (e.g. 0.019% LOD)

Anti-pyrogen

piping of "no weld techniques" and valves.

Anti-pyrogen

piping of "no weld techniques" and valves.

Anti-pyrogen

walls of inner drum, mirror finish.

Anti-pyrogen

walls of inner drum, mirror finish.

Machine

design complying with GMP, WHO and FDA standards,

Machine

design complying with GMP, WHO and FDA standards,

as well as YOUR requirements.

Great economy

with lowest water consumption per batch and only

Great economy

with lowest water consumption per batch and only

nominal compressed air consumption.

|

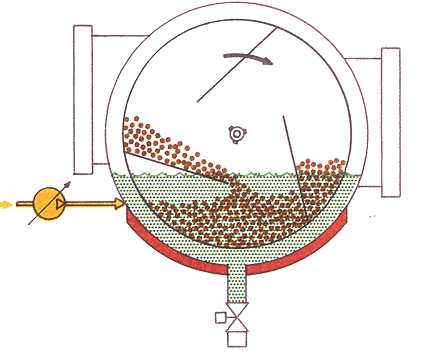

Loading

Loading is effected from the non

sterile side under sterile air stream coming out of the machine. No particles from the room

can thus enter the machine.

|

|

|

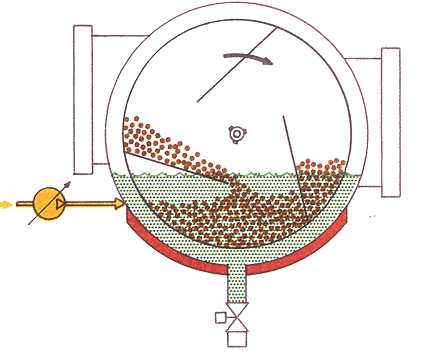

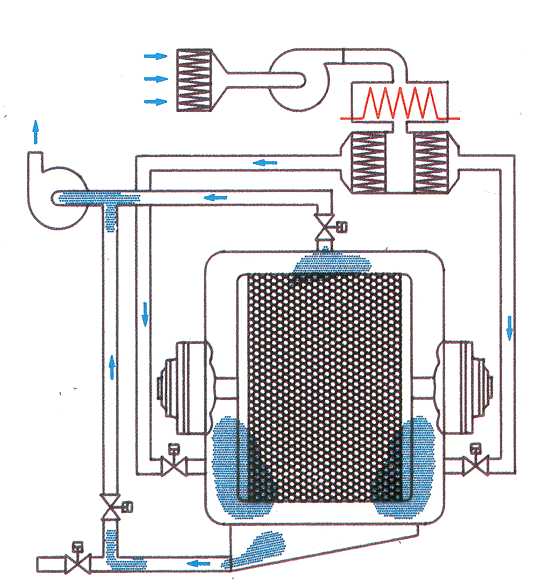

Washing/Detergent

Dosing

After the water supply has reached the

set level, detergent is added by the dosing unit. When the inner drum starts rotating,

simultaneously the heating process starts.

|

|

|

CIP System

When the washing water is drained off,

the CIP Machine-self cleaning starts. The outer cylinder and inner drum are cleaned

by rotating high pressure jets in order to avoid re deposits of flushed particles and silicone.

|

|

|

SIP - System

On request, at SIP step can be

integrated. This insures a precise vaporization of the inner wall of the pressure vessel by rotating steam nozzles, thus having a high

cleaning efficiency.

|

|

|

Rinsing/Siliconization

After refilling the machine with hot

water, the articles are rinsed.

If necessary, the articles can now be siliconized. This is done by adding the required quantity of silicone by means of the dosing unit. Either silicone oil or silicone emulsion can be used.

|

|

|

Subaqual-Sterilization

On request, the machine can be designed

in such a way that a subaqual pre-sterilization of the stoppers in a water

bath under pressure up to a temperature of about 125 degrees Celsius can

be carried through. Subaqual pre-sterilization serves for extraction of foreign components and for releasing substances which can hardly be removed or chemical

contamination out of the rubber stoppers. Thus, direct positive influence

on leaching of the inner substances of stoppers and thus on drug

stability.

|

|

|

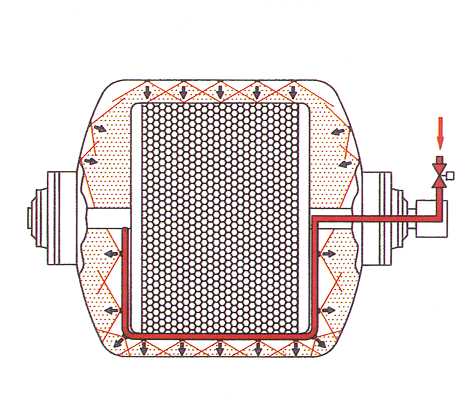

Sterilization

Steam is supplied through nozzles of

the center shaft

(patented). By the steam stream coming from the center, a fast removal of the oxygen rich atmosphere from the pressure vessel is achieved. On request, even pre-vacuum for sterilization

is possible. The steam continuously and uniformly supplied via the nozzles

guarantees an optimum temperature

distribution and the machine quickly reaches the required

sterilizing temperature of 121 degrees Celsius. During sterilization, the stoppers are smoothly shifted from time

to time. Pressure and temperatures are permanently recorded

according to FDA.

|

|

|

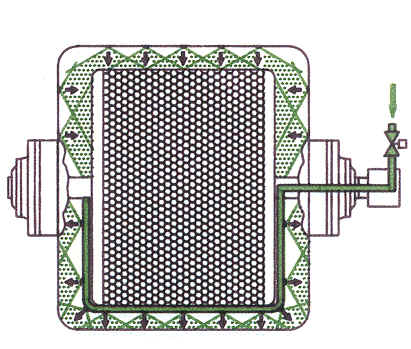

Drying

The air required for the drying step is

pressed into the machine

via a pre-filter, blower and .02 micron sterile filter (HEPA filtered air

is optional). Drying is done by occasional

intermittent shifting of the stoppers and simultaneously passing through

sterile air, thus avoiding any friction as with other systems. For

products requiring low residual moisture, hot air register and vacuum are

available as a support. With a vacuum unit, automatic leak test can be

carried out. At the end of drying, cooling down of stoppers to unloading

temperature is effected, therefore no after condensation of stoppers in

the filling containers. Instead of inline sterilizable

filter cartridges with 0.2 micron Hepa filters can be used.

|

|

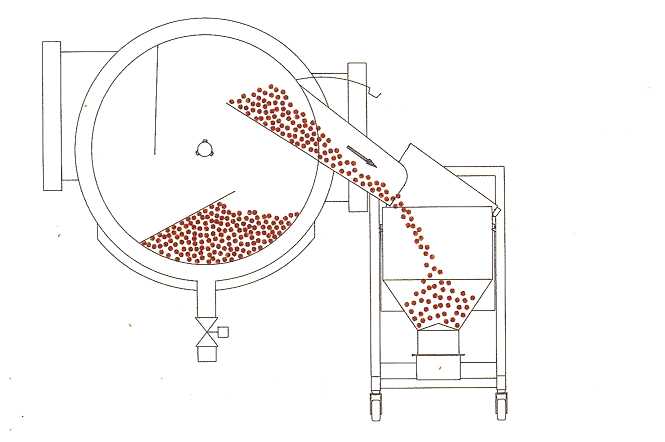

| Unloading

For unloading, stopper transfer and easy feeding to filling lines,

HUBER has available:

Design according to YOUR request are possible.

Sterile Isolation System SIS or Total Sterile Transfer TST permit transfer of stoppers from the DS S

to the filling and stoppering machines without any break in the sterile

chain and on demand, sterile storage for days.

For more information

Stopper Handling

|

|